5 AXIS MACHINING CENTRE

The major structure parts are manufactured from high quality Meehanite cast iron, tempered for stress relief. A/C adopt DD motor ensure the high accuracy and efficient. The 5-axis synchronized machining saves machining time reduces repetitive workpiece setup and error,while dramatically increasing machining and accuracy. Pinnacle AX170/ AX320/ AX450/ AX500 are proven to be super machines for high efficiency and accuracy.

FEATURES

- 320 x 320 x 380 mm Travel

- A Axis Tilt 240° (-120°/+120°)

- C Axis Rotary 360°

- Rapid Feedrate 36/36/36

- 3.7/9.5 Kw Spindle Motor

- ISO40 Spindle Taper

- X, Y & Z Axis Linear Way

Rigid, Stable, Accurate

Rigid, Stable, Accurate

RUGGEDLY CONSTRUCTED THROUGHOUT TO PROVTDE LIFETIME ACCURACY YEAR AFTER YEAR

- The major structural parts are manufactured form high quality Meehanite cast iron (GB 300), tempered for stress relief with hardness over 190HB.

- 25mm Roller type linear ways on X, Y, Z axis increased stability.

- X, Y, Z axis are transmitted with class C3, Ø28mm ball screws.

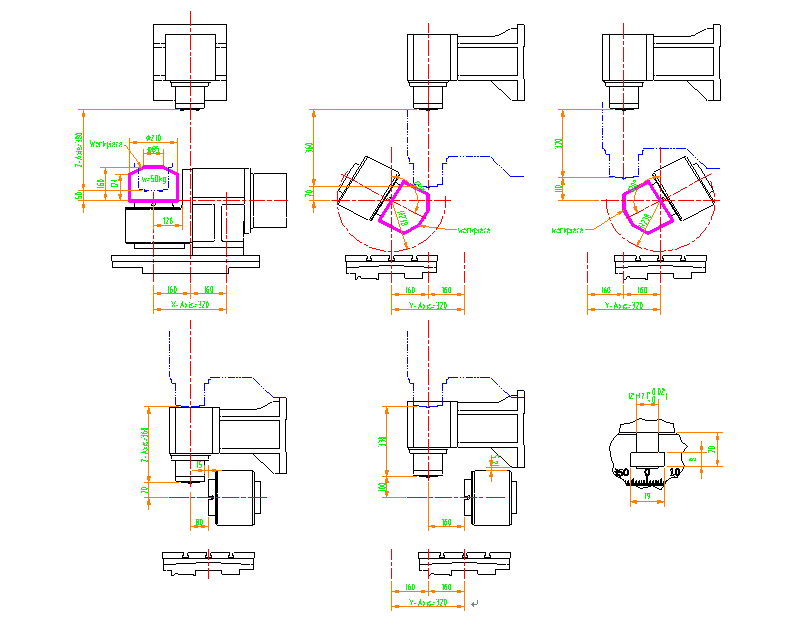

5 Axes Rotary Table

- Rotary Table diameter Ø170

- Table rotation and tilting are driven by DD motor

- A/C-axes rotary speed: 60/200rpm

- Rositioning accuracy, A/C-axis: 5"/5"

- Repeatibility accuracy, A/C-axis: 8"/4"

Specifications

| MODEL | AX170 |

| TABLE | |

| Table Size (mm) | Ø170 |

| Travel Ranges (X/Y/Z mm) | 320 / 320 / 380 |

| Spindle Nose to Table Surface(mm) | 50~430 |

| Max. Table Load (kgs) | 50 |

| Max Workpiece Size (WxH mm) | Ø210 x 160 |

| Diameter of Table Hole (mm) | Ø40 |

| A-Axis, Title (deg) | ±120° |

| C-Axis, Rotary (deg) | 360° |

| A-Axis Max. Rapid Speed (rpm) | 60 |

| C-Axis Max. Rapid Speed (rpm) | 200 |

| T Slot Size | 14 x 90° x 4 |

| SPINDLE | |

| Tool Shank & Pull Stud | ISO40 (HSKA63) |

| Spindle Max Speed (rpm) | 15000 |

| Spindle Base Speed (rpm) | 2000 |

| Spindle Power (S1/max kW) | 3.7 / 9.5 |

| Spindle Torque (S1/max Nm) | 18 / 45 |

| Spindle Type | Direct |

| Spindle Bearing Inner Diameter (mm) | Ø60 |

| AXIS SERVO MOTOR | |

| Rapid Feed Rate (XY/Z m/min) | 36 / 36 / 36 |

| Cutting Speed (X/Y/Z mm/min) | 20000 |

| X/Y/Z-axes Rated Torque (Nm) | 1.5 / 1.5 / 2.1 |

| A-Axis Rate Torque (Nm) D.D motor | 205 |

| C-Axis Rate Torque (Nm) D.D motor | 35 |

| AUTO TOOL CHANGER | |

| ATC Type | DISK |

| Cam Type | ARM TYPE |

| Tool Selection (Bi-Direction) | RANDOM |

| Tool Storage Capacity (PCs) | 20 |

| Max. Tool Diameter (mm) | Ø75 |

| Max. Tool Length (mm) | 250 |

| Max. Tool Weight (Kgs) | 8 |

| MISCELLANEOUS | |

| Positioning Accuracy X/Y/Z(mm) | 0.005 |

| A/C(arc-sec) | 5" / 5" |

| Repeatability Accuracy X/Y/Z(mm) | 0.003 |

| A/C(arc-sec) | 8"/4" |

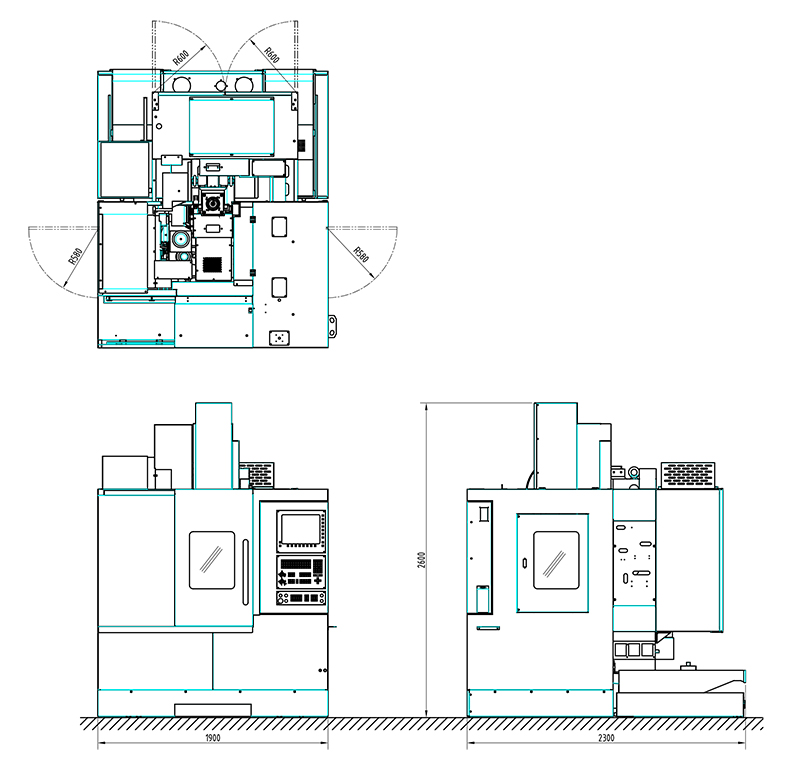

| Floor Space (mm) | 1900 x 2110 x 2550 |

| Machine Weight (Kgs) | 2800 |

All Specifications And Designs Are Subject To Change Without Notice.

Table Size

Floor Space

Accessories

ACCESSORIES

- Air Blast

- Air Blast for Workpiece

- 3 Axes Telescopic Covers

- Full Splash Guard

- Auto Lubrication System

- A-Axis Rotary Encoder

- C-Axis Rotary Encoder

- Working Lamp

- Operation Status Light

- Cooling System

- Air Gun / Water Gun

- HR510 MPG

- A/C for Electronic Cabinet

- USB-RJ45 Interface

- Heidenhain TNC640

- DCM

- Kinematice

- Spindle Oil Cooler

- Adjusting Tools and Box

- 20-Arm Type ATC

- Leveling Bolts and Pads

- Manuals

CONTROL SYSTEM

- Transformer

- Coolant Through Spindle

- Tool measurement system

- Worpiece Measurement sytem