DOUBLE COLUMN MACHINING CENTRE

DV14 series Double Column Machining center that fully combines heavy cutting and high speed machining capabilities in one. The DV14 series is a profitable performer especially excellent for precision machining for extra heavy parts. To ensure maximum stability when handling heavy parts machining, the five major structural parts of the machine are manufactured from high quality Meehanite cast iron and ductile iron. The specially designed machine structure enables the machine to keep at the best accuracy condition after years of operation. With the roller type linear guide ways on X, Y, Z axis, the machine fully exhibits it heavy loading resistance and outstanding features.

To meet the high speed, high precision machining requirement, the DV14 series employs a direct-drive high speed spindle. This combines with a high / low speed gearbox for transmission with the wide speed range. It makes the machine ideal for high speed machining. In addition, the gearbox also provides high torque output, permitting the machine to perform heavy cutting with ease. The spindle head on the DV14 series is designed with advanced automatic compensation balancing system combined with the use of accumulator to control hydraulic cylinder, allowing the spindle to move smoothly and steadily at all times.

FEATURES

- All major structural parts are manufactured from high quality cast iron with tempering tread to relieve stress, ensuring maximum material stability without deformation.

- Box type structural parts are rib reinforced to increase structural strength and rigidity.

- Extra heavy base complete support of table and resists heavy load without deformation.

- X, Y, Z axis are mounted with roller type linear ways combined with extra wide between ways for added stability.

Features

RIGID SPINDLE HEAD

- The spindle head is a box-type construction that increases stability when performing heavy loading.

- The linear ways on Z axis are specially designed with side layout to upgrade rigidity of the spindle head.

GEAR BOX

- This spindle running is transmitted through a gear box, making the machine excellent for heavy cutting applications.

- Wide spindle speed range from 10 to 6,000 rpm permit the machine to perform heavy cutting and fine finishing.

- All gears and bearings in the gear box are oil-bath lubricated.

32 TOOLS CHAIN TYPE MAGAZINE (STANDARD)

- The magazine is driven by a precision cam, featuring fast and accurate tool positioning.

- Tool selection is bi-directional and random for fast tool change.

- The magazine accepts ISO 50 tool shank.

- The magazine is separately mounted from the cutting area combined with a protection door to prevent tools contamination from chips or coolant.

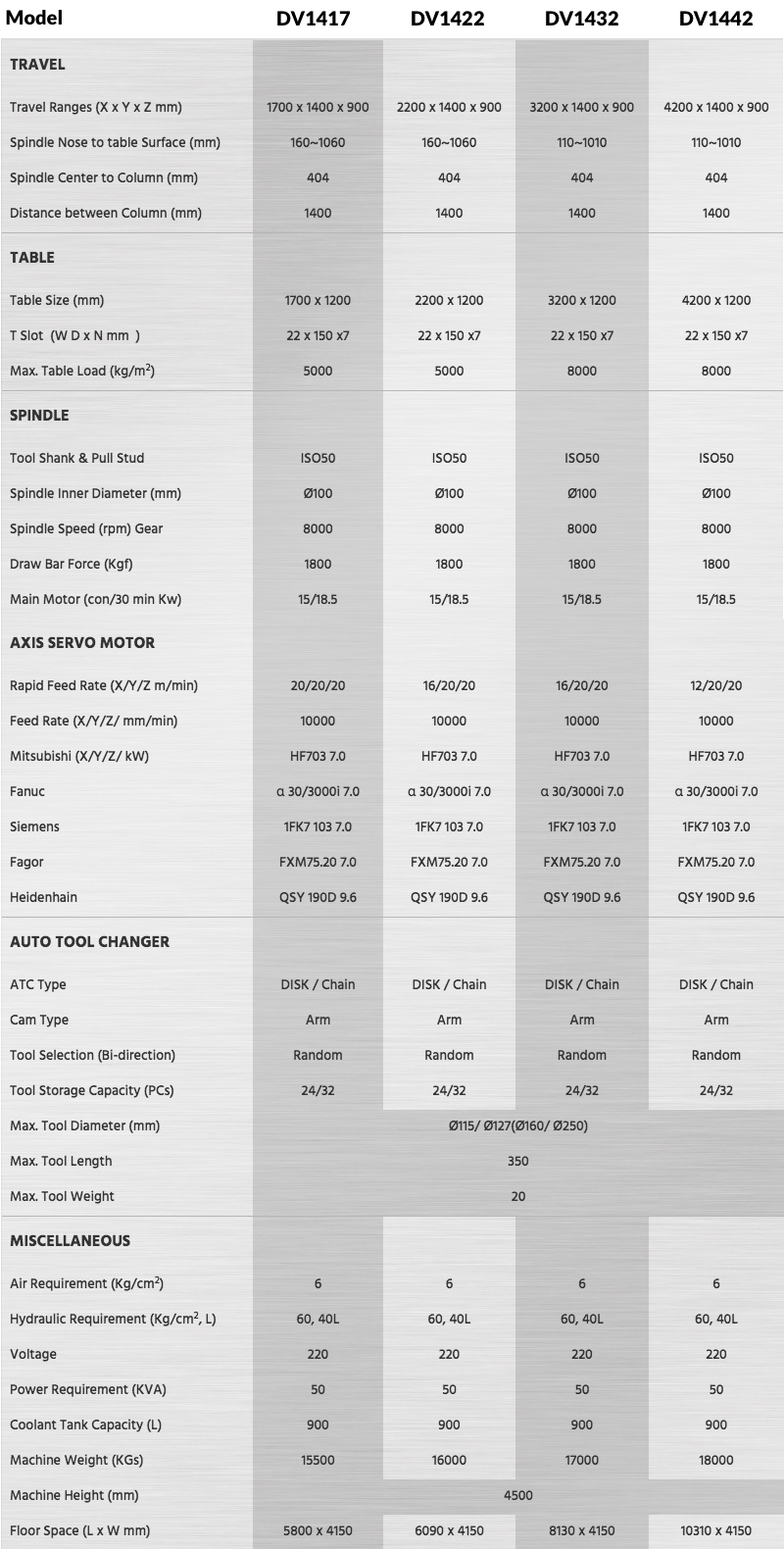

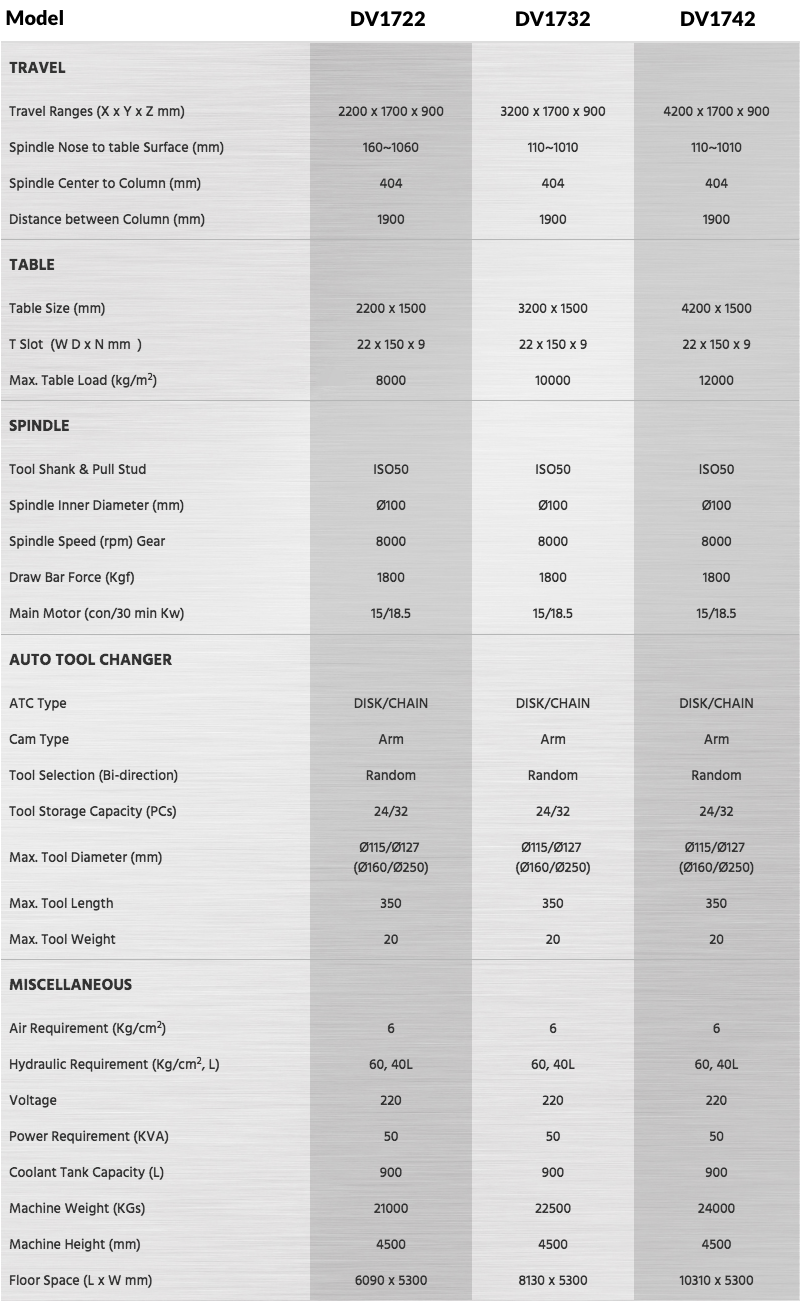

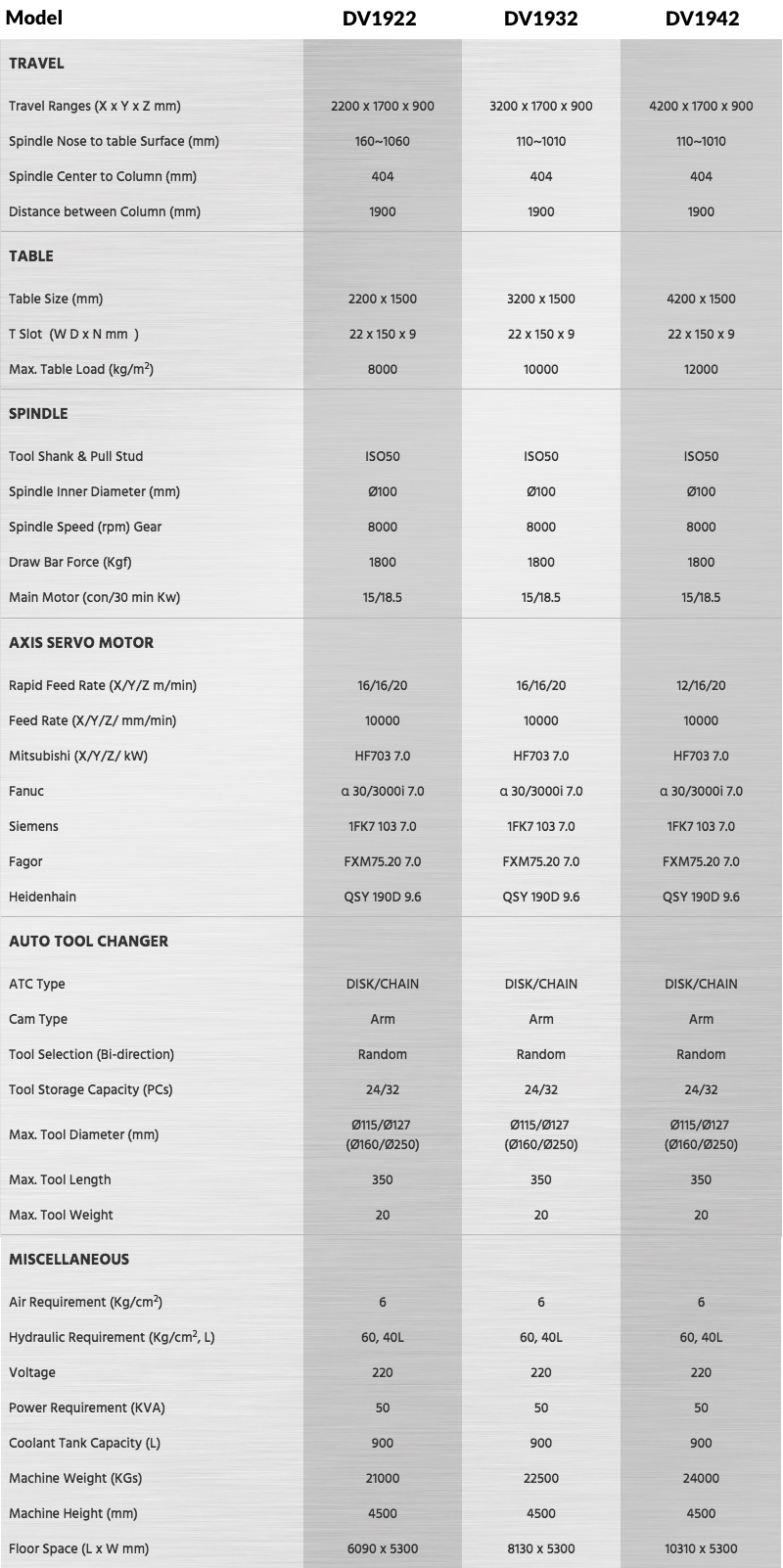

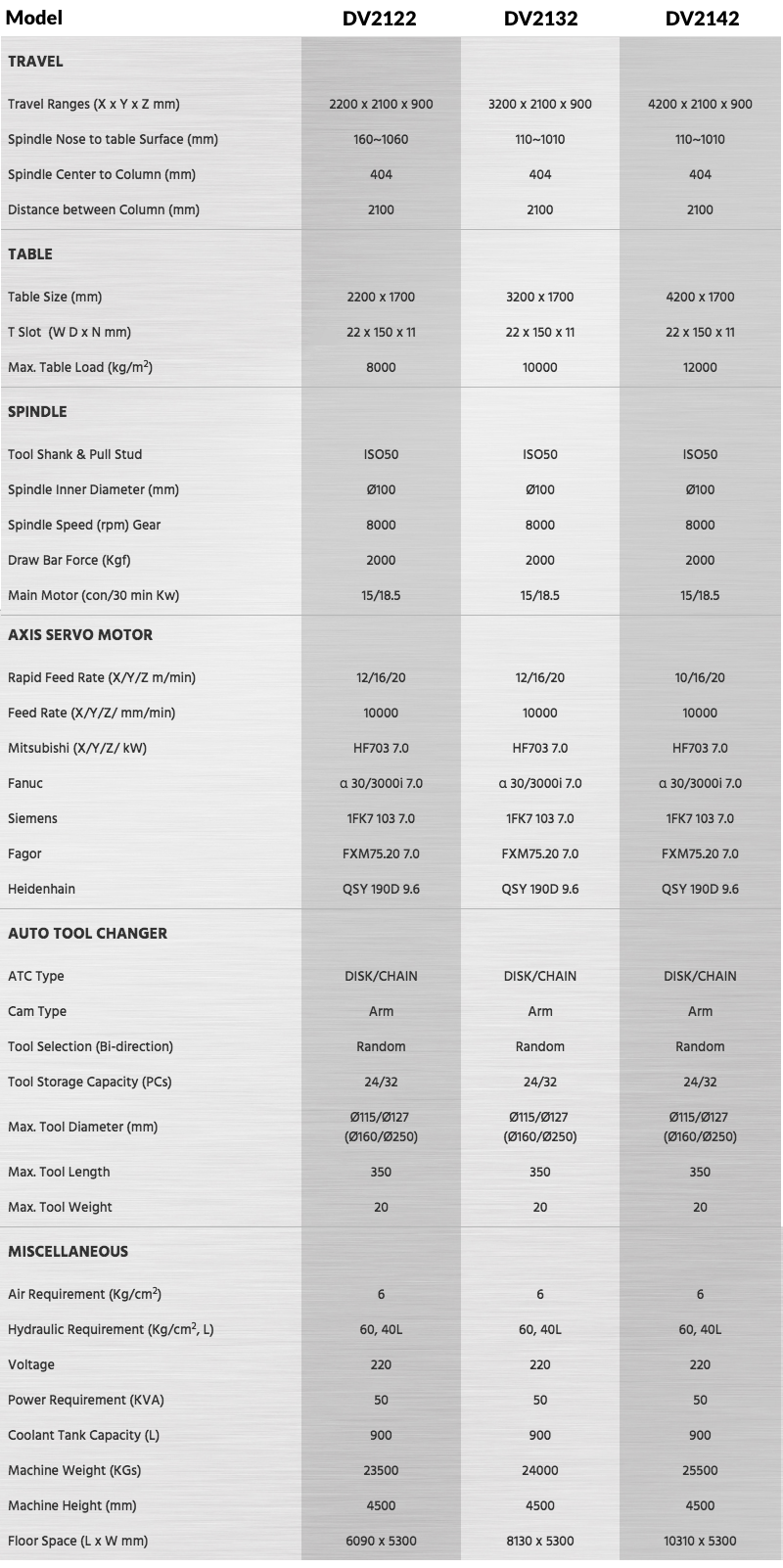

Specifications

Accessories

STANDARD ACCESSORIES

- Air blast through spindle

- Air blast for workpiece (nose)

- Automatic lubrication system

- Working lamp

- Operation status light

- Screw type chip conveyors

- Chain type 32-tool ATC

- Gear head

- Cooling System

- Z axis pneumatic balance system

- Air gun / water gun

- MPG handwheel

- Heat exchanger

- RS-232 Interface

- Rigid tapping

- Spindle oil cooler

- Tool box

- Leveling bolts and pads

- Operation and programming manual

- Semi-full splash safety guard

OPTIONS

- Z-travel: 1100mm

- Extend column: 300mm

- Full Splash Guard

- Coolant through Spindle

- Linear Scales

- Auto tool length measurement

- Auto workpiece measurement

- Manual Universal Head (90°)

- Auto Universal Head (90°)

- Rotary table

- Adjusting Tools and box

- Foundation bolt