5 AXIS MACHINING CENTRE

The major structure parts are manufactured from high quality Meehanite cast iron, tempered for stress relief. The spindle head elevation employs a pneumatic type balance system to minimize the spindle head vibration during moving.

The 5-axis synchronized machining saves machining time reduces repetitive workpiece setup and error,while dramatically increasing machining and accuracy.

Pinnacle AX320/ AX450 are proven to be super machines for high efficiency and accuracy.

FEATURES

- 660 x 610 x 610 mm Travel

- A Axis Tilt 150° (-120°/+30°)

- C Axis Rotary 360°

- Rapid Feedrate 30/30/24

- 9/12 Kw Spindle Motor

- ISO40 Spindle Taper

- X, Y & Z Axis Linear Way

Rigid, Stable, Accurate

Rigid, Stable, Accurate

RUGGEDLY CONSTRUCTED THROUGHOUT TO PROVTDE LIFETIME ACCURACY YEAR AFTER YEAR

- The major structural parts are manufactured form high quality Meehanite cast iron (GB 300), tempered for stress relief with hardness over 190HB.

- Roller type linear ways on X, Y, Z axis increased stability.

- X, Y, Z axis are transmitted with class C3, Ø40mm ball screws.

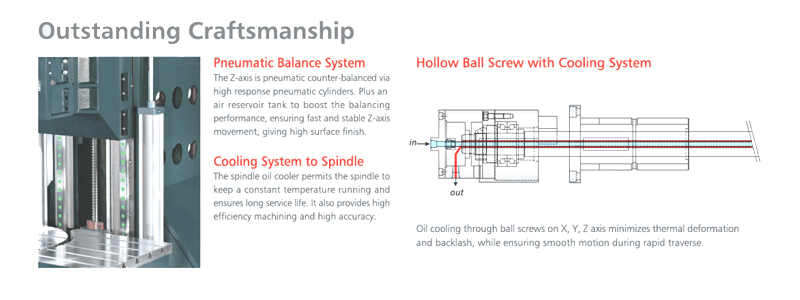

HOLLOW BALL SCREW WITH COOLING SYSTEM

Oil cooling through ball screws on X, Y, Z axis minimizes thermal deformation and backlash, while ensuring smooth motion during rapid traverse.

PNEUMATIC BALANCE SYSTEM

The Z-axis is pneumatic counter-balanced via high response pneumatic cylinders. Plus an air reservoir tank to boost the balancing performance, ensuring fast and stable Z-axis movement, giving high surface finish.

COOLING SYSTEM TO SPINDLE

The spindle oil cooler permits the spindle to keep a constant temperature running and ensures long service life. It also provides high efficiency machining and high accuracy.

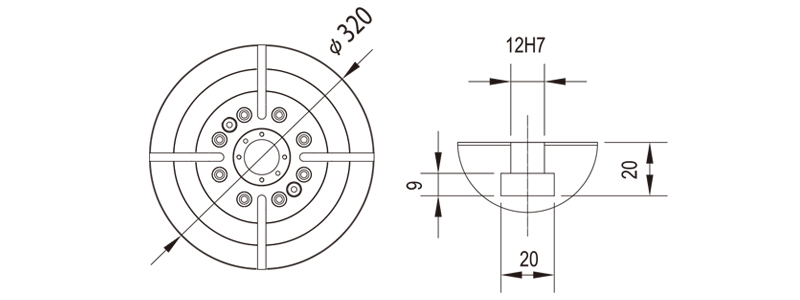

5 Axes Rotary Table

- Rotary Table diameter Ø320 / Ø450mm

- Table rotation and tilting are driven by servo motor

- Rositioning accuracy, A/C-axis: 15"/10"

- Repeatibility accuracy, A/C-axis: 10"/8"

Specifications

| MODEL | AX320 |

| TABLE | |

| Table Size (mm) | Ø320 |

| Travel Ranges (X x Y x Z mm) | 660 x 610 x 610 |

| T Slot Size (Size x deg ) | 12 x 90 |

| Max. Table Load (0°/90°) | 150/150 |

| Max. Workpiece Size (W x H mm) | Ø420x 300 |

| Diameter of Table Hole (mm) | Ø50 |

| Spindle Nose to Table Surface (mm) | 50~605 |

| A Axis, Tilt (deg)/(0.001°) | 150°(-120°/+30°) |

| C Axis, Rotary (deg)/(0.001°) | 360° |

| SPINDLE | |

| Tool Shank & Pull Stud | ISO40 |

| Spindle Inner Diameter (mm) | Ø70 |

| Spindle Speed (rpm) Direct drive | 10000 (12000/15000) |

| Spindle Speed (rpm) Built-in | 18000 (20000/24000) |

| Main Motor (con/30 min Kw) | 9/12 |

| AXIS SERVO MOTOR | |

| Rapid Feed Rate (X/Y/Z m/min) | 30/30/24 |

| Feed Rate (X/Y/Z/ m/min) | 10 |

| Feed Rate (A/C rev/min) | 5.5/11.5 |

| X Axis Rated Torque (Nm) | 10 |

| Y Axis Rated Torque (Nm) | 10 |

| Z Axis Rated Torque (Nm) | 10 |

| A Axis Rated Torque (Nm) | 5 |

| C Axis Rated Torque (Nm) | 3.8 |

| AUTO TOOL CHANGER | |

| ATC Type | DISK - 24,30(Chain-40) |

| Cam Type | ARM |

| Tool Selection (Bi-direction) | RANDOM |

| Tool Storage Capacity (PCs) | 24 (30,40) |

| Max. Tool Diameter (mm) | 90 (76) |

| Max. Tool Length | 300 |

| Max. Tool Weight | 8 |

| MISCELLANEOUS | |

| Air Requirement (Kg/cm2) | 6 |

| Hydraulic Requirement (Kg/cm2, L) | 40, 30L |

| Voltage | 380 |

| Power Requirement (KVA) | 40 |

| Coolant Tank Capacity (L) | 300 |

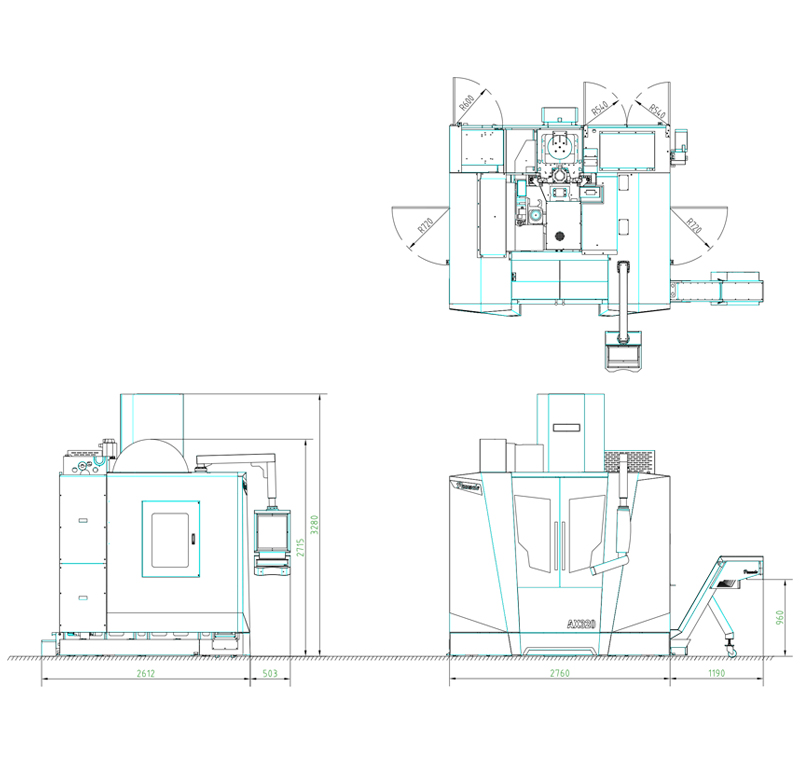

| Machine Weight (KGs) | 6500 |

| Machine Height (mm) | 2900 |

| Floor Space (L x W mm) | 2660 x 2230 |

| Packing Size (L x W x H mm) | 2660 x 2230 x 2560 |

All Specifications And Designs Are Subject To Change Without Notice.

TABLE SIZE

FLOOR SPACE

Accessories

ACCESSORIES

Air blast through spindle

Air blast for workpiece (nose)

Coolant flushing system

- 3 axes telescopic covers

- Full splash guard

- Automatic lubrication system

- Working lamp

- Operation status light

- Arm type 24-tool ATC

- Z axis pneumatic balance system

- Cooling System

- Air gun / water gun

- MPG handwheel

- Heat exchanger

- RS-232 Interface

- Rigid tapping

- Spindle oil cooler

- Hollow ball screws with cooling system

- A-axis Rotary Encoder

- C-axis Rotary Encoder

- Adjusting Tools and box

- Leveling bolts and pads

- Operation and programming manual

CONTROL SYSTEM

- Transformer

- Chain type chip conveyor

- Coolant through Spindle

- 3 Axes Linear Scales

- Auto tool length measurement

- Auto workpiece measurement

- FANUC Controller

- MITSUBISHI Controller

- SIEMENS Controller