Linear Way Series

When jobs call for highly efficient machining and when outstanding accuracy is critical, a Pinnacle linear way series vertical machining center is the perfect solution. The LV300B(D) / LV500B(D) is a multifaceted series. It is not only ideal for smaller factories and machine shops. It covers applications ranging from watch and time pieces to 3C and 4C industries. It is also ideal for manufacturing molds for joints, teeth and bones used in the medical industry. If you are serious about increasing machine productivity and profits, the Pinnacle linear way series can really help you.

FEATURES

- Rapid Feedrate 48/48/48 m/min

- 3.7 / 5.5KW Spindle Motor

- X, Y & Z Axis Linear Way

- 24,000 rpm Built-in spindle (ISO30 – LV500B)

- 12,000 rpm Direct-Drive spindle (ISO30 – LV500D)

- 10,000 rpm Direct-Drive spindle (ISO40 – LV500)

The Best Possible Structural Design

LV500B/ LV500D / LV500

Rapid Feedrate 48/48/48 m/min3.7 / 5.5KW Spindle Motor

X, Y & Z Axis Linear Way

24,000 rpm Built-in spindle (ISO30 – LV500B)

12,000 rpm Direct-Drive spindle (ISO30 – LV500D)

10,000 rpm Direct-Drive spindle (ISO40 – LV500)

RUGGED CONSTRUCTION ASSURES OPTIMUM RIGIDITY AND STABILITY.

Supported by superior precision P4 class bearings, the spindle provides an extra wide range of machining capacity and high speed.

Floating unclamping system assures tool unclamping force will not transmit to the spindle bearings. It provides stable tool clamping and unclamping with the spindle and extends the spindle bearings' life.

The spindle is a cartridge-type.

Choice of various spindle speeds - Direct-drive 12,000 rpm.

Building-in 24,000 rpm.

The circulating oil cooling system on the spindle head prevents thermal expansion and offers the best precision machining environment.

RIGID, PRECISION SPINDLE

ASSURES HIGH QUALITY MACHINING

Supported by superior precision P4 class bearings, the spindle provides an extra wide range of machining capacity and high speed.

Floating unclamping system assures tool unclamping force will not transmit to the spindle bearings. It provides stable tool clamping and unclamping with the spindle and extends the spindle bearings' life.

The spindle is a cartridge-type.

Choice of various spindle speeds - 8,000, 10,000 and 12,000 rpm.

The circulating oil cooling system on the spindle head prevents thermal expansion and offers the best precision machining environment.

ARM TYPE ATC

The 20-tool arm type magazine is activated by electric motor transmitted by U-cam mechanism, featured with the fastest tool change speed and it bi siewxrionL Ensom tool selection. (option for LV300 / LV500)

CHIPS FLUSHING NOZZLES

Coolant flushing nozzles on rear inner wall of guard prevent jam of chips during operation.

WATER CURTAIN ON SPINDLE (OPTION)

The spindle can be mounted with water curtain device. In conjunction with graphite filtration device (separator and filter bag), the machine is ideal for graphite machining. It prevents graphite dust from splashing to the working environment which may causes damage to the operators health and circuit board in the control box.

AUTOMATIC LUBRICATION SYSTEM

The Lubrication System automatically measures and accurately distributes the oil to the slide ways, ballscrews and bearings.

SPLASH GUARD

The full-enclosed splash guard meets environmental protection and CE requirements. It offers users a comfortable working environment.

CONTROL SYSTEM

The centralized control panel employs a touch sensing screen for user-friendly operation. The humanized designed control panel has an elegant appearance. Various controllers can be chose - Mitsubishi, Heidenhain, Fanuc and Siemens.

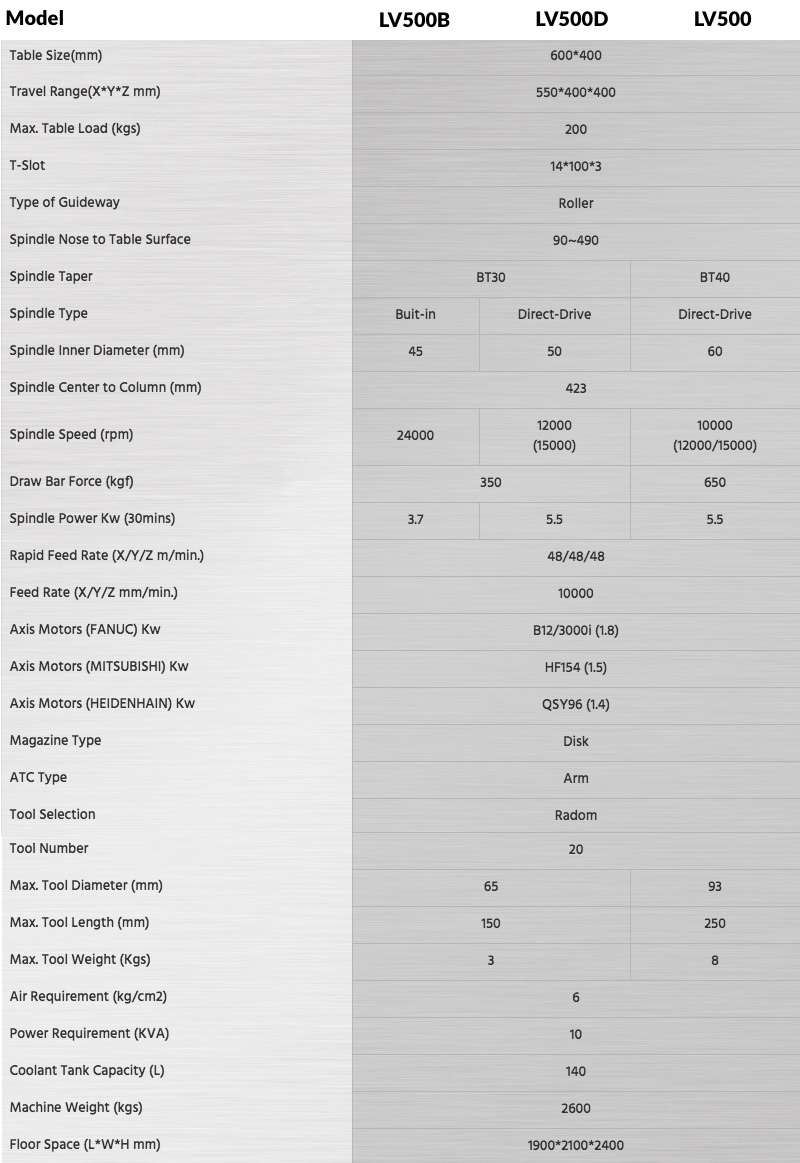

Specifications

Accessories

ACCESSORIES

- Air blast through spindle

- Air blast for workpiece (nose)

- Coolant flushing system

- 3 axes telescopic covers

- Full splash guard

- Centralized automatic lubrication system

- Working lamp

- Operation status light

- Cooling system

- Air gun and water spray-gun

- MPG handwheel

- Heat exchanger

- RS-232 Interface

- Rigid tapping

- Spindle oil cooler

- Adjusting tools and box

- Leveling bolts and pads

- Operation and programming manual

CONTROL SYSTEM

- MITSUBISHI M80 / M830

- FANUC 0i-MF / 31i-MB

- HEIDENHAIN TNC620 / TNC640

- SIEMENS 828D / 840D

- FAGOR 8055i Plus / 8060FL / 8060